Headphone Hanger

Ben Gillette · December 20th, 2019

My first 3D Fusion 360 project was to create a mounting hook to hang my headphones on the wall next to my computer using a 3D printer. I had to create it so that the hook would be able to hold and support my headphones, and also stick to the wall. I chose to create this hook because the headphones in the office in my house always sit around, and can be stepped on. In addition, it's nice to keep the area organized and I wanted to add an icon to the hook to differentiate between others in the room and make it look a little better.

My first step in the process was to make some quick drafts to see what shape I liked best for the hooks. At this point I was pretty much set on having a baseplate of some shape with a hook rod coming out of it. My first draft shape wise was a plain circle with a hook coming out of it. I didn’t end up using it because it just looked a little too bland, and didn’t maximize surface area so that the hook would stay on the wall.

My new problem was how I would maximize the surface area of the hook so that it sticks on the wall (I had to use tape to attach it) without making an obscenely large baseplate. My solution was to make an elliptical shape, so that there would be a longer face to promote “stickage” and the scale between the longer base and the hook arm looks much cleaner than my initial design. Another problem I fixed here was adding an end piece that keeps the headphones from sliding off the hook. I also fileted the edges of the hook and plate so that shape looked slightly cleaner than having hard edges.

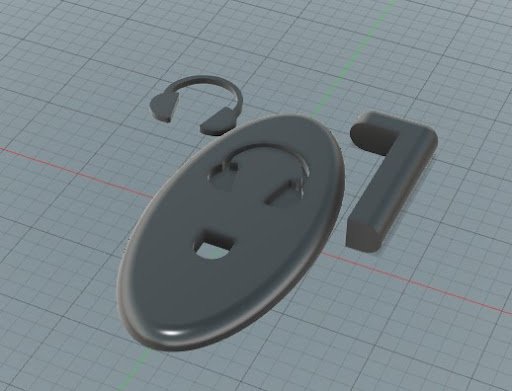

The next step was to make the file print ready. Because the hook has the end part that prevents the headphones from sliding off, I couldn’t print the entire piece as a whole, so I had to lay it on its side next to the hook. The problem with this of course is that just gluing the hook to the baseplate isn’t the best joint possible, and would likely break. To fix this, I cut out a hole big enough for the hook so the two could be connected much more securely after printing. Having that hole in the baseplate is also actually more sturdy that if I could print the piece as a whole, because if you think about the layers during printing being stacked on top of eachother, there is only one layer holding the hook to the baseplate (when it’s printed flat). So adding a hole to connect the hook in post was actually not only better for printing, but also better for structural integrity of the final product.

The only problem at this point was cosmetic. The top of the baseplate seemed rather empty, and I also had other hooks in the room that I wanted to differentiate this one between. To fix both these problems with one solution, I decided to trace out a little headphone icon on the top portion of the baseplate. I did this by looking up an image online, and pasting it on a blank fusion project as a canvas. I used the slip line tool to trace the outline, then extruded it into a small icon. I then linked it onto the hook file, and extruded a copy into the baseplate, making the indent you see on the left. This looked pretty good to me, and at the same time differentiated it between other hooks in the room making it more unique. In addition the layout was ready to print, so my next step was to make it.

The print settings I used were standard print resolution with a couple small supports underneath the hook. These were incredibly small and the minimal possible amount I could have used because only a few were needed to support the curve of the fillet on the hook piece. Because of the supports, I printed on a raft, and all advanced settings were standard. I printed my design using a flash forge finder.

I’m very happy with how the hook turned out. It works perfectly and holds even more weight without any strain. Overall, it looks good, functions as I intended it to, and is an original design. I appropriately sized it for its use, as the headset fits perfectly and the baseplate sticks to the wall perfectly while also not looking too clunky. Finally, I used the minimal amount of support material by printing the hook on its side along with the base plate and attaching it separately.